Flange hole marking formula pdf

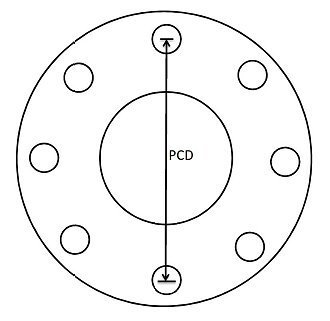

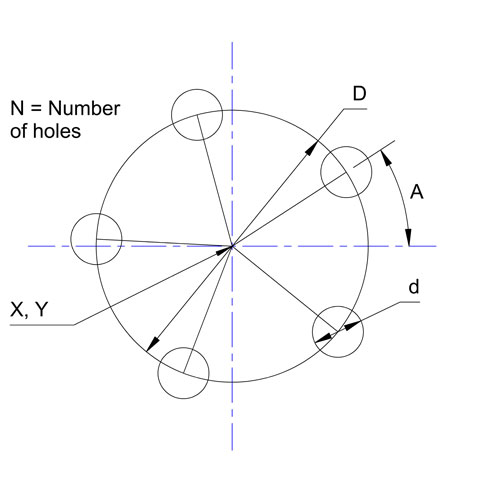

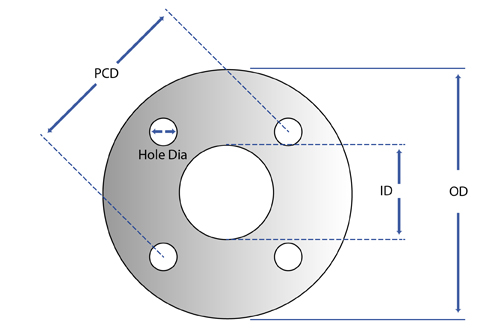

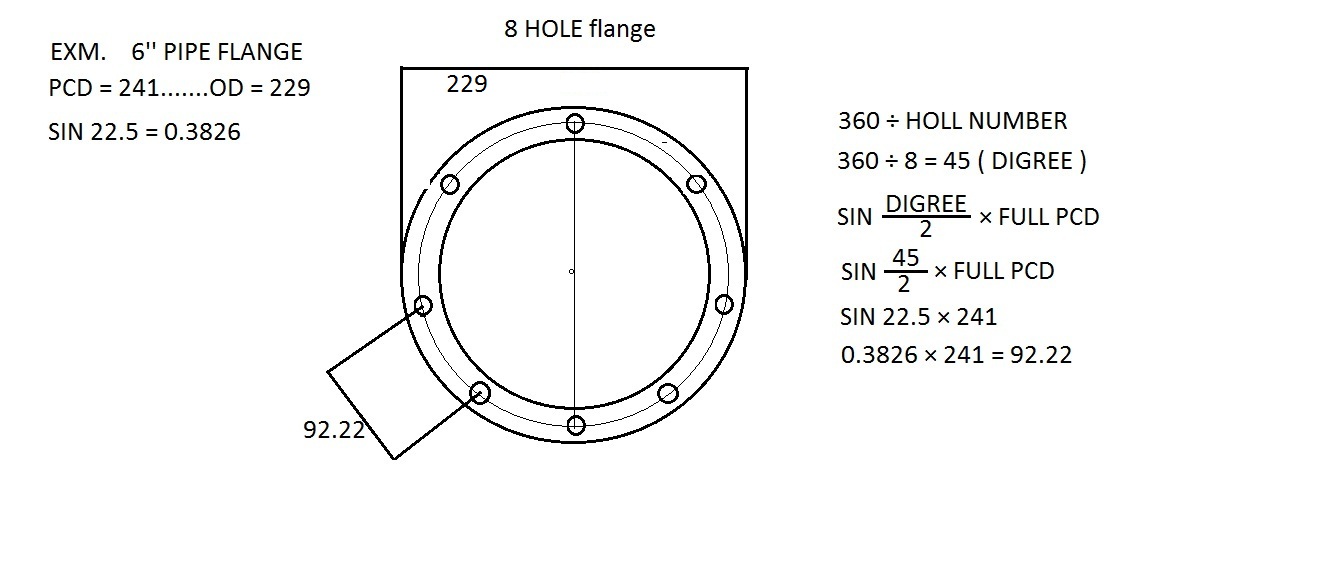

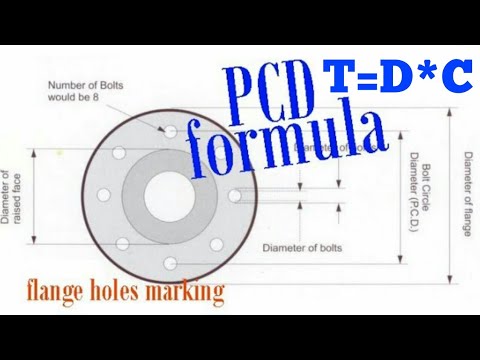

PCD of a flange can be calculated from 4 holes or Stud. Let us learn how to calculate PCD of 4, 5 and 6 hole flange. Formula for Pitch Circle Diameter of a Flange :

a triangle is formed by two adjacent holes and the center of the flange opening this is an isosceles triangle with a vertex angle of 45º (1/8 of 360º) and a side length of 2.25″ the distance between centers is the base (b) of the triangle

allowance formula commonly incorporates the degrees to radians conversion. When a part has a gusset in a formed flange, the gusseted area will generally form “high” as the gusset drives material beyond the expected development. NEUTRAL AXIS GUSSETS DRIVE MATERIAL. Bend Allowance Overview SheetMetalDesign.com Page 12 of 12 6. PDF Version A printable PDF version of this …

the flange and the wheel at (A). This ensures that clamping pressure is exerted only at This ensures that clamping pressure is exerted only at the centre of the hub section.

is not available, rub chalk on the flange faces to make. Figure 2-29.–Bisecting an angle. the drawn lines clearly visible. 3. Locate the center of each flange with a surface. gauge, or use a center head and rule combination if. To bisect an angle, let’s assume angle ABC. the flange diameter is relatively small. (See view A, (fig. 2-29) is given. With B as a center, draw an arc. fig. 2-24 and

Sensor boxes SRBC q/w Festo core product range Covers 80% of your automation tasks Worldwide: Always in stock Superb: Festo quality at an attractive price Easy: Reduces procurement and storing complexity qReady for dispatch from the Festo factory in 24 hours Held in stock in 13 service centres worldwide More than 2200 products wReady for dispatch in 5 days maximum from stock Assembled …

bolt tightening sequence for api flanges. Lubricate bolt and nut threads and nut bearing face (where it contacts the flange). After flange assembly and all nuts have been run down by hand, start wrench tightening following the sequence of the numbers indicated (marking the number on the flange with a crayon aids in keeping track of the tightening process).

Bolt Holes for Flanges. Just as already circumscribed, ASME B16.5 is also de standard for the number and the diameter of the bolt holes in a flange. The numbers and diameters diverge per Pressure Class, but is for every typ of flange in a specific Pressure Class the same. The bolt holes are be similar divided over the diameter of the bolt circle, and the number is always an even number (4, 8

15/10/2014 · Hi, Come across a job the other day where I had to make a circular plate with 3 holes in it to hold in a pin, the 3 holes were 90mm apart in a triangle, as the machine was broken down (for this reason) a strap was welded across to get the machine working, i want to make the plate spot on but dont really know where to start with marking out a

Individual manual marking and drilling of holes Errors are probable within each hole group and between groups. Satisfactory for small isolated hole groups only. Match marking Achieved by pre-drilling approximately half the holes in the components, then assem-bling the components in their calculated relative geometry and marking the holes through. The components are then disman-tled and drilled

This Video shows how to mark center of bolt holes of flanges & Dividing of circle in no of part. this video will helpful for fabricator. Link for this Calculator Mobile App:

Bolt Holes centres for sections Introduction The back mark is the distance from the back of an angle or channel web to the centre of a hole through the leg or flange.

bent flanges. In low carbon the edge of a hole is the radius of the curl plus the material thickness. The minimum distance a curl should be from an internal bend is six times the material thickness plus the radius of the curl. The minimum distance a curl should be from an external bend is nine times the material thickness plus the radius of the curl. Dimples The maximum diameter should be

Calculate Flange (General Example) mltech.co.uk

LAYING OUT VALVE FLANGE BOLT HOLES tpub.com

The rules for the marking of systems, equipment and components are uniformly defined in the standards relating to the general technical requirements – EN 13463-1 for mechanical equipment. A priority for all Ex equipment and protective systems is that the marking should show the areas of their

It covers forged steel flanges, sizes NPS 1/2 (DN 15) through NPS 24 (DN 600). CSA CSA standard CAN3-Z245 12-M96 covers the manufacture, dimensions, tolerances and …

22/12/2017 · For a flange with no easy access to the actual centre, try the cheating way: Draw everything, flange inner, outer & PCD on a cad program to scale, (any decent program will do a pcd from a centre point) print out the drawing, glue (Pritt stick) the diagram to the flange…

Welding Neck (WN): this type of flange is designed to be joined to the pipe by buttwelding, so if you intent to direct weld a flange in an elbow, you need to use this one, as the other types need a straight part to be fitted inside de flange.

issue date: june 6, 1995 revision a june 11, 2002 awhem recommendation for interchangeable stud bolts and tap end studs for api spec 6a flanges issued by:

To mark off the bolt holes in a flange the set squares can be used for a flange having 3 or 6 holes, the 60° set square is used and for flange having 4 or 8 holes, the 45° set square.

Flange orientation based on a consistent frame of reference (see Bolt Hole Orientation Standard for a full description of flange orientation) Flange centre-line direction (Horizontal)

Table 16-2.–Constant Values for Locating Center of Flange Boltholes: Hull Maintenance Technician Page Navigation 548 549 550 551 552 553 554 555 556 557 558

If the flanges repaired by welding, it must mark on flanges showing this flange repared by welding. If the flange’s dimensions (OD, ID, PCD, Thickness, Holes number, Holes diameter, Tolerance etc) are different with the normal standard, it also must mark on flanges where it is different with normal ones. Another important place is heat number marking, it is the tracing base for every piece

2/03/2012 · The quantity of flanges is completely unrelated to the number of holes. 2. There are no standard ANSI flanges with 6 bolt holes. Not sure about DIN flanges. 3. The pitch circle diameter is… 2. There are no standard ANSI flanges with 6 bolt holes.

bolt tightening sequence for flanges using 12 bolts. Lubricate bolt and nut threads and nut bearing face (where it contacts the flange). After flange assembly and all nuts have been run down by hand, start wrench tightening following the sequence of the numbers indicated (marking the number on the flange with a crayon aids in keeping track of the tightening process).

SHEET METAL TOOLS 1 – ROPER WHITNEY HAND PUNCH Punches up to 1/4” hole through 16 ga. metal. Sold either as an individual tool or as a complete kit in a case with 7 punches and dies for 3/32” to 9/32” holes.

manufacture of the flange hole of the 96 pipe sleeve, through the selection of hardware, such as drill bits, machine tools, gears, shafts, and the simulation of Ansysworkbench force of main parts, obtain the design device and the processing method suitable

A counterbore (symbol: ⌴) is a cylindrical flat-bottomed hole that enlarges another coaxial hole, or the tool used to create that feature. A counterbore hole is typically used when a fastener, such as a socket head cap screw , is required to sit flush with or below the level of a workpiece’s surface.

Spec SBHP-898/Replaces SBHP-586 ALL STATED SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE OR OBLIGATION. F = 2″ Standard (11/2″ – 3″ Optional)

There are also more complicated marking tools from different manufacturers. There are Master Markers and Miter Markers with On-Off Magnetic Blocks by Flange Wizard. There are Contour Markers by Curv-O-Mark in Standard and Jumbo. How about Circle-Ellipse Projectors and Multi-hole Imagers. Have you ever heard of a Plumber’s Rule for 45° offsets?

MARKING: All Flanges when possible will display a heat number, size, table, grade and dimensional standard PLATE STEEL FLANGES: Plate flanges are mainly used for light duty, lower pressure or non-critical applications, commonly

475 KLUG CIRCLE • CORONA, CA 92880-6406 (951) 280-4488 • FAX: (951) 272-4445 A DIVISION OF TRIPAC MARKETING, INC. PROPER FLANGE BOLTING Flanges In theory, if …

1/06/2013 · Hi all can anyone help with a simple formula to calculate the pcd of a set of holes… i know how many holes i have and i also know the center distance between the holes i just need the formula to find what pcd it is.. i just wanted a quick way of working out a pcd without drawing it up in master…

or no currency or recognition in today’s flange or valve piping codes or standards. Furthermore, from the ‘yes’ reply it should not be construed that this is the only required product marking.

use of set squares to divide a circle into a number of equal parts. Back To mark off the bolt holes in a flange the set squares can be used for a flange having 3 or 6 holes, the 60° set square is used and for flange having 4 or 8 holes, the 45° set square.

2/03/2012 · Re: Pitch circle diameter formula for flanges 03/02/2012 4:16 AM In Automobile and refrigeration industry, 2 bolt flanges and 3 bolt flanges with tongue and groove joints are also used.

the flange of the column using angles, with one leg extended along the girder flange and the other against the column. The function of the girders is to support the intermediate floor beams. pipe

marking off 5 hole flange. You search Auto repair manual PDF marking off 5 hole flange, if there are search results will appear below. If search results do not exist, please search by others keyword.

Pipefitter.com > Tools > Marking Tools

the formula for piers is:. Pi x the raduis squared x the depth. Ie a 400 mm diameter pier 1.2 metres deep would be:. 3.14 x .2 (200mm)x .2(200mm) x 1.20(1200mm) = .150 cubi…c metres Begin

Hole-to-form-distance from hole-to-form—to avoid hole distortion, place holes no less than 2.5 times the material thickness + bend radius from the bend itself. Slot-to-form- long slots should be spaced 4 X the material thickness plus the bend radius.

After choosing ‘I want to make a ring of holes’ you will see this display. You can now select the number of holes you want, the radius or diameter (set diameter mode) of your hole (the calculation is unitless, whatever you supply, will be output, so a radius if ‘1’ as above can be 1 meter, 1 inch, or 1 centimeter, the output is in the same units). – wine bottle planter tutorial 7/10/2008 · Upload failed. Please upload a file larger than 100×100 pixels; We are experiencing some problems, please try again. You can only upload files of type PNG, JPG, or JPEG.

6/02/2012 · The one I use for really accurate hole location is not to mark out at all, but to find the edge(s) of the metal with an edge finder and to located the holes by co-ordinate drilling. I have a 3-axis DRO on my milling machine, which is all I ever use for metal drilling, and this method locates the holes within 10 microns or so.

Definition and Details of Flanges – Bolt Hole Orientation Bolt Holes for Flanges Just as already circumscribed, ASME B16.5 is also de standard for the number and …

21/07/2008 · The formulas I use for the position of angular holes are called vectors R sin theta = X component R cos theta = Y component R= radius Theta is the angular position of the hole. The symbol for Theta is θ . As I recall it the 12 o’clock position is angular zero if the center of the bolt circle is X0 Y0 but I would have to play a bit to confirm my memory there. So a 4 hole pattern with the first

Training: Calculate Flange (General Example) Calculate Flange (General Example) Description The following describes the calculation method for in situ flange survey.

4 User benefits • All items available from a single equipment supplier. Spirax Sarco orifice plate flowmeters – the system M240G Steam flow computer

The flange dimensions listed in this guideline conform to the Standards nominated. Metal backing flanges with reduced thickness are used by industry for non-critical, low performance applications and are not recommended by PIPA.

rotation of flanges shall be as stated in Figure 1 and Figure 2. Closer tolerances on weld end preparations than stated in Figure 1 and Figure 2, may be specified in the relevant welding specification for the material in question,

Flange Weight Chart, flange weight calculator, flange weight calculation, wnrf flange weight calculator, flanges weight calculator, tongue and groove flange, blind flange weight calculator, weld neck flange …

Hole distance measurement (centre to centre) 1. Zero positioning and measurement between two holes Assemble FMS hole distance inserts as shown in FMS holders (e.g. 10A or 11A) on a digital caliper Insert both FMS hole distance inserts in one hole and zero the caliper Insert a FMS hole distance insert in each hole – the caliper will now display the distance between hole centres. 2. Holes evenly

To “One-Hole” a flange means that the flange has been rotated so that one hole is right on the natural centerline. I assure you that 99.999% of the time that to “One Hole” a flange is a mistake and will add cost to the field. It also makes the piping foreman very unhappy.

2/04/2010 · I have to mark out 5 holes equally spaced on a 72mm dia, whats the formula again ? I know its 72 deg but i havent got a dividing head, ,i have compass,dividers and vernier caliper etc. thanks Matt ps Like on a car wheel stud pattern, 5 studs. pcd=72mm

Ball valves Key features and product range overview Version Type Process valve connection Nominal width DN Flange hole pattern to ISO 5211 Process valve nominal pressure PN Page/Internet Stainless steel 2-way, with pipe thread to EN 10226-1 VZBA-…-GG Rp1/4 8 F0304 63 7 Rp3/8 10 F0304 Rp1/2 15 F0304 Rp3/4 20 F0304 Rp1 25 F0405 Rp1 1/4 32 F0405 Rp1 1/2 40 F0507 Rp2 50 F0507 Rp2 1/2 65 …

Maths formula for circumference pcd Motorcycle

Quick Reference Flange Chart PN6 5K 125 lbs PN10 10K 150 lbs PN16 16K 300 lbs PN25 20K 300 lbs PN40 40K 600 lbs O.D. B.C. HOLES O.D. B.C. HOLES O.D. B.C. HOLES O.D. B.C. HOLES O.D. B.C. HOLES

The way to work out any sequence on a even number holed flange is to start of with 1,3,2,4 sequence. You will then add 4 to each number until you reach the total value number … of holes.

Piping Designers . com Section – 6C Flanges

PITCH CIRCLE CHORDAL DISTANCE CALCULATION ptsintl.com

SOLUTION There are eight holes equally spaced on the

Marking out / drilling holes in precisley the correct

Marking Off 5 Hole Flange Motorcycles Repair Manual

Bolt hole circle practicalmachinist.com

STANDARD BOLT HOLE PATTERN DATA Ruskin

– ASTM A182 FLANGES ANSI B16.5 INDEX Ta Chen

Pcd Formula Industrial Forum – eMastercam.com

Angle Section dimensions RoyMech

Flanges Marking ANSI (ASME) B16.5 Flange AWWA C207

PITCH CIRCLE CHORDAL DISTANCE CALCULATION ptsintl.com

ASME B16.5 Pipe Flanges and Flanged Fittings Published

2/04/2010 · I have to mark out 5 holes equally spaced on a 72mm dia, whats the formula again ? I know its 72 deg but i havent got a dividing head, ,i have compass,dividers and vernier caliper etc. thanks Matt ps Like on a car wheel stud pattern, 5 studs. pcd=72mm

Definition and Details of Flanges – Bolt Hole Orientation Bolt Holes for Flanges Just as already circumscribed, ASME B16.5 is also de standard for the number and …

the formula for piers is:. Pi x the raduis squared x the depth. Ie a 400 mm diameter pier 1.2 metres deep would be:. 3.14 x .2 (200mm)x .2(200mm) x 1.20(1200mm) = .150 cubi…c metres Begin

manufacture of the flange hole of the 96 pipe sleeve, through the selection of hardware, such as drill bits, machine tools, gears, shafts, and the simulation of Ansysworkbench force of main parts, obtain the design device and the processing method suitable

4 User benefits • All items available from a single equipment supplier. Spirax Sarco orifice plate flowmeters – the system M240G Steam flow computer

2/03/2012 · The quantity of flanges is completely unrelated to the number of holes. 2. There are no standard ANSI flanges with 6 bolt holes. Not sure about DIN flanges. 3. The pitch circle diameter is… 2. There are no standard ANSI flanges with 6 bolt holes.

Flange Weight Chart, flange weight calculator, flange weight calculation, wnrf flange weight calculator, flanges weight calculator, tongue and groove flange, blind flange weight calculator, weld neck flange …

2/03/2012 · Re: Pitch circle diameter formula for flanges 03/02/2012 4:16 AM In Automobile and refrigeration industry, 2 bolt flanges and 3 bolt flanges with tongue and groove joints are also used.