manual propress

The Manual ProPress is a cutting-edge tool designed for efficient and precise pressing operations․ It offers unparalleled control, durability, and ease of use, making it ideal for various applications․

1․1 Overview of ProPress Technology

ProPress technology represents a significant advancement in pressing systems, offering a user-friendly, efficient, and durable solution․ Designed for precision and reliability, it integrates advanced mechanisms to ensure consistent results across various applications․ Its robust construction and ergonomic design make it suitable for both professional and DIY projects․ The technology emphasizes ease of use, with intuitive controls and minimal maintenance requirements․ ProPress systems are widely adopted in industries requiring high-quality pressing outcomes, delivering superior performance and long-term durability․ This innovative approach ensures that users achieve professional-grade results with minimal effort, making it a preferred choice for modern applications․

Key Features and Components of ProPress

ProPress boasts advanced features like precision pressing, durable construction, and user-friendly controls․ Its modular design ensures adaptability, while its robust components guarantee reliable performance across various tasks․

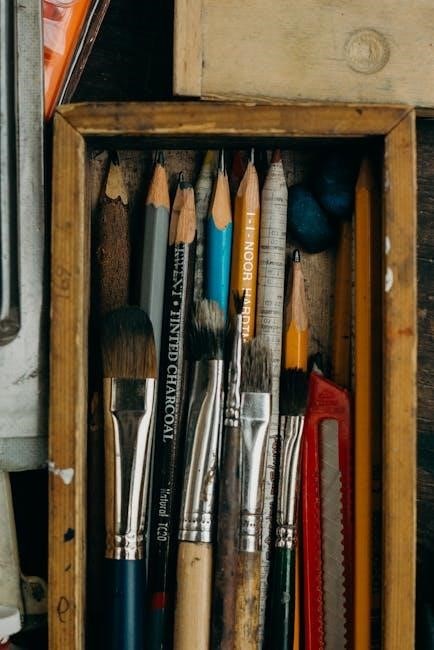

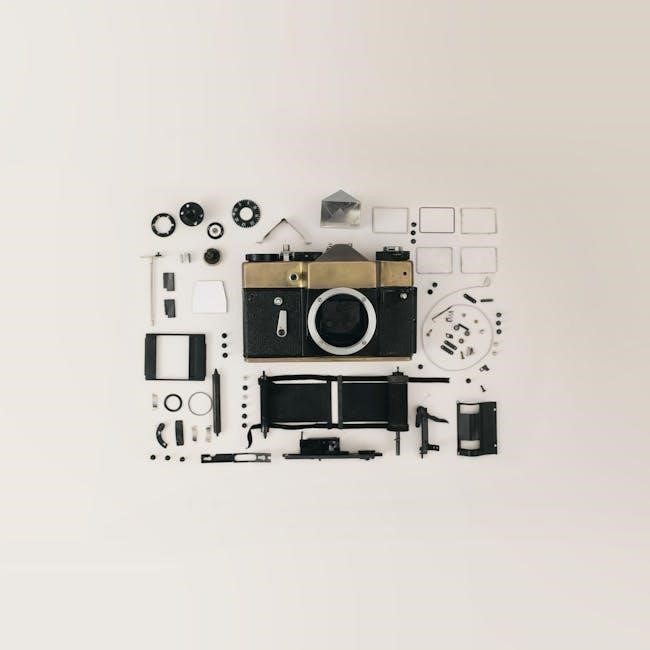

2․1 Detailed Breakdown of ProPress Tools and Accessories

The ProPress system includes a range of tools and accessories designed for precision and efficiency․ The primary press tool features a durable, high-grade steel frame and an ergonomic handle for comfortable operation․ It is accompanied by interchangeable dies, which are tailored for specific pressing tasks․ Additional accessories include pressure gauges, adapters, and alignment guides to ensure accurate and consistent results․ The system also comes with a storage case to keep all components organized․ Each tool is crafted with premium materials, ensuring longevity and reliability․ These accessories collectively enhance the ProPress experience, making it a versatile solution for diverse applications․

Installation and Setup Guide

Install the ProPress system by first unpacking and assembling the components․ Align the tool according to the manufacturer’s guidelines and secure it firmly․ Ensure all connections are tight and calibrated properly for optimal performance․ Follow the step-by-step instructions provided in the manual to complete the setup efficiently․ Always refer to the safety precautions to avoid any potential risks during the installation process․ Once installed, test the system to confirm its functionality before proceeding with operations․ Proper setup ensures precision and durability, making the ProPress a reliable tool for your tasks․ Regular maintenance will extend its lifespan and maintain performance quality over time․ By adhering to the installation guide, you can maximize the effectiveness of the ProPress system and achieve professional results consistently․

3․1 Step-by-Step Instructions for ProPress System Installation

Begin by unpacking the ProPress components and ensuring all parts are included․ Carefully read the manual to understand the installation process․ Start by assembling the base unit and aligning it with the work surface․ Secure the tool using the provided mounting hardware, ensuring stability․ Next, connect the hydraulic or pneumatic system, following the pressure specifications outlined in the manual․ Calibrate the press according to the manufacturer’s guidelines to achieve precise operation․ Finally, test the system with a trial run to ensure proper functionality․ Refer to the troubleshooting section if any issues arise during setup․ Proper installation ensures safe and efficient operation of the ProPress system․

Advanced Features of ProPress

The ProPress offers advanced features like customizable settings, precision control, and automated pressure adjustment, ensuring consistent results․ These features enhance efficiency and adaptability for complex tasks․

4․1 Exploring Special Functions and Settings

The ProPress system includes a variety of special functions designed to optimize performance․ Users can customize pressure settings, adjust operation modes, and utilize advanced diagnostic tools for troubleshooting; The system also features integrated safety mechanisms, such as automatic shut-off and pressure monitoring, to ensure safe operation․ Additionally, the ProPress allows for seamless integration with other tools and accessories, enhancing its versatility․ By exploring these features, users can unlock the full potential of the ProPress, achieving precise and efficient results in various applications․ These settings cater to both novice and advanced users, providing flexibility and control․

Troubleshooting Common Issues

Identify and resolve issues quickly with the ProPress troubleshooting guide․ Common problems include malfunctioning parts or connectivity issues, often resolved by resetting or replacing components․ Ensure proper maintenance․

5․1 Diagnosing and Resolving ProPress-Related Problems

Diagnosing ProPress issues begins with identifying error messages or unusual behavior․ Common problems include faulty connections, misaligned components, or software glitches․ Start by restarting the system and ensuring all cables are securely connected․ If issues persist, check for firmware updates or recalibrate the tool․ For mechanical problems, inspect for worn parts and replace them as needed․ Regular maintenance, such as cleaning and lubricating moving parts, can prevent many issues․ Always refer to the user manual for specific troubleshooting steps․ If problems remain unresolved, contact professional support for assistance․ Consistent upkeep ensures optimal performance and extends the lifespan of your ProPress system․

Maintenance and Safety Precautions

Regularly inspect and clean the ProPress system to ensure optimal performance․ Lubricate moving parts and replace worn components promptly․ Always follow safety guidelines to avoid accidents․

6․1 Best Practices for Long-Term ProPress Performance

To maintain peak performance, regularly inspect the ProPress for wear and tear․ Clean the tool after each use to prevent debris buildup․ Lubricate all moving parts periodically to reduce friction and extend lifespan․ Store the ProPress in a dry, cool environment to avoid corrosion․ Always follow the manufacturer’s guidelines for maintenance and safety․ Proper handling and storage ensure reliability and longevity of the tool․ By adhering to these best practices, users can maximize efficiency and maintain consistent results over time․

Compatibility with Other Systems

ProPress is designed to integrate seamlessly with various systems, ensuring compatibility across plumbing, HVAC, and industrial setups․ Its adaptability enhances workflow and performance in diverse applications․

7․1 Integrating ProPress with Existing Infrastructure

Integrating ProPress with existing infrastructure is straightforward, thanks to its universal compatibility․ The system supports various pipe materials, including copper, PEX, and stainless steel․ Adapters and conversion kits are available to ensure smooth transitions between systems․ ProPress tools are designed to work seamlessly with standard plumbing and HVAC setups, minimizing downtime․ Additionally, the system’s modular design allows for easy upgrades without major overhauls․ This adaptability makes ProPress a versatile solution for both new installations and retrofit projects, ensuring efficiency and reliability in any setting․

Frequently Asked Questions (FAQs)

What is ProPress? ProPress is a reliable, high-performance pressing system designed for various applications․ How does it work? It uses precision engineering for secure connections․ Can it be repaired? Yes, with genuine parts․ Is it compatible with existing systems? Absolutely, with adapters available․ How long does it last? With proper maintenance, it offers long-term durability․ Where can I find support? Visit the official website or contact certified distributors for assistance and resources․

8․1 Addressing Common User Queries About ProPress

What is the ProPress system? It is a high-performance pressing solution designed for efficiency and durability․ How do I maintain it? Regular cleaning and lubrication are essential․ Can it be used with other systems? Yes, adapters are available for compatibility․ What if I encounter issues? Troubleshooting guides and support teams are accessible online․ Where can I find replacement parts? Genuine parts are available through authorized distributors․ Is training required? While not mandatory, tutorials and manuals are provided for optimal use․ How long is the warranty? Warranty details vary by model and region․ For specific queries, visit the official ProPress support page or contact customer service․

The Manual ProPress is a versatile, efficient, and durable tool that simplifies pressing tasks․ Its robust design and ease of use make it ideal for various industrial applications․

9․1 Summary of ProPress Benefits and Future Prospects

The Manual ProPress offers exceptional efficiency, precision, and durability, making it a reliable choice for professional and industrial applications․ Its robust design ensures long-term performance, while its ease of use enhances productivity․ The tool’s versatility allows it to adapt to various tasks, making it a valuable asset in different industries․ Looking ahead, advancements in technology, such as AI integration and IoT connectivity, could further enhance its capabilities, offering real-time monitoring and smarter operations․ With a focus on sustainability, future models may incorporate eco-friendly materials, aligning with global environmental goals․ The ProPress is poised to remain a leading solution in its field․

Additional Resources

Explore official ProPress websites, user manuals, and online forums for detailed guides, troubleshooting tips, and expert advice to maximize your ProPress experience and performance․

10․1 Where to Find More Information and Support

For comprehensive support and resources, visit the official ProPress website, which offers detailed manuals, FAQs, and troubleshooting guides․ Additionally, explore community forums and YouTube tutorials for hands-on demonstrations and user experiences․ Contact customer support directly for personalized assistance․ You can also find authorized distributors for genuine parts and accessories․ Stay updated with the latest software updates and product news to ensure optimal performance․ These resources provide a complete ecosystem to enhance your ProPress usage and address any challenges effectively․

Archives

Calendar

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 | 30 | 31 |

Leave a Reply

You must be logged in to post a comment.