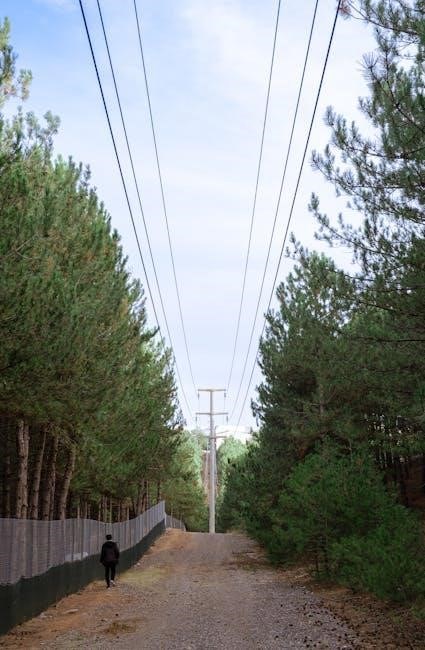

guide wire for power pole

Guide wires are essential components in power distribution systems‚ providing structural support and ensuring the stability of overhead power lines. They play a critical role in maintaining reliable electricity supply by protecting lines from environmental stresses and mechanical damage.

1.1 Definition and Purpose

A guide wire‚ also known as a messenger wire‚ is a sturdy steel cable used in power distribution systems to provide structural support and maintain tension for overhead power lines. Its primary purpose is to ensure the stability and alignment of conductors‚ preventing sagging or damage from environmental factors like wind or ice. Guide wires also serve as a protective barrier‚ reducing the risk of power line damage during installation or maintenance. They are essential for maintaining reliable electricity supply and are typically installed alongside power poles to create a secure and durable infrastructure.

1.2 Importance in Power Distribution Systems

Guide wires are crucial for ensuring the reliability and efficiency of power distribution systems. By maintaining proper tension and alignment of overhead conductors‚ they prevent power outages caused by sagging lines or mechanical damage. Additionally‚ guide wires protect lines from environmental stresses such as strong winds‚ ice‚ and extreme temperatures‚ which can lead to costly repairs and service interruptions. Their role in stabilizing infrastructure ensures consistent energy delivery‚ making them indispensable in modern power distribution networks. Without guide wires‚ maintaining grid stability and reliability would be significantly challenging‚ especially in areas prone to harsh weather conditions.

Types of Guide Wires

Guide wires are categorized by material composition‚ such as steel‚ aluminum‚ or composite materials‚ each offering unique strength‚ durability‚ and conductivity for varying power distribution needs.

2.1 Material Composition

Guide wires are made from materials like steel‚ aluminum‚ and composites. Steel offers high tensile strength and durability‚ while aluminum provides excellent conductivity and corrosion resistance. Composite materials combine strength and light weight‚ enhancing performance in harsh environments. Each material is selected based on specific application requirements‚ ensuring optimal performance in power distribution systems. Proper material choice is crucial for longevity and reliability‚ addressing environmental factors like weather and mechanical stress. This selection directly impacts the overall efficiency and safety of the power distribution network.

2.2 Size and Gauge Specifications

The size and gauge of guide wires are critical for ensuring proper functionality and safety. Gauge refers to the wire’s thickness‚ with lower numbers indicating thicker wires. Common gauges range from 6 AWG to 4 AWG‚ selected based on load requirements. The wire’s diameter must match the intended application to handle stress and environmental factors. Proper sizing ensures optimal flexibility‚ durability‚ and resistance to weather conditions. Incorrect gauge or size can lead to inefficiency or failure‚ making accurate specifications essential for reliable power distribution systems. Regular inspections ensure compliance with industry standards and maintain system integrity over time.

Installation and Configuration

Installation involves securing guide wires to power poles using proper techniques‚ ensuring alignment and tension are within specified limits for optimal performance and safety. Regular inspections are crucial.

3.1 Tools and Equipment Required

Installing guide wires requires specialized tools‚ including winches for tensioning‚ wire grips for secure handling‚ and tension meters to ensure proper stress levels. Safety equipment like hard hats‚ gloves‚ and harnesses is essential. Additionally‚ climbing gear‚ such as gaffs and belts‚ allows linemen to ascend poles safely. Crimping tools and connectors are used to secure wires‚ while transportation equipment like trucks or aerial lifts may be needed for accessing high poles. Proper tools ensure efficient and safe installation‚ minimizing risks and ensuring durability.

3.2 Step-by-Step Installation Process

Begin by planning the guide wire route‚ ensuring minimal interference with existing structures. Prepare the power poles by attaching insulators and anchors. Next‚ unravel and lay the guide wire along the planned path. Use a winch to tension the wire‚ securing it to anchors at both ends. Ensure proper alignment and tension to withstand environmental stresses. Finally‚ inspect the installation for any sagging or loose connections‚ making adjustments as needed. This systematic approach ensures a durable and reliable setup for power distribution.

3.3 Challenges During Installation

Installing guide wires for power poles presents several challenges. Environmental factors like rough terrain and harsh weather conditions can complicate the process. Ensuring proper tension to prevent sagging or damage is critical. Additionally‚ aligning the guide wire accurately with the power line requires precision. Safety risks‚ such as working at heights or near live wires‚ demand specialized equipment and training. Coordination between multiple teams and equipment compatibility further add to the complexity. Addressing these challenges ensures a reliable and safe installation‚ minimizing future maintenance issues and enhancing overall system performance.

Maintenance and Inspection

Regular maintenance and inspection of guide wires ensure long-term reliability and safety. Inspections involve checking for wear‚ corrosion‚ and damage‚ while maintenance includes cleaning and tension adjustments.

4.1 Regular Inspection Techniques

Regular inspections of guide wires involve visual examinations for signs of wear‚ corrosion‚ or damage. Technicians use specialized tools to measure wire tension and ensure proper alignment. Thermal imaging can detect overheating issues‚ while drones equipped with cameras provide detailed aerial assessments. Inspectors also check for vegetation interference and wildlife damage. Documentation of findings is crucial for tracking maintenance needs and scheduling repairs. Routine inspections help prevent failures‚ ensuring reliable power distribution and safety for both equipment and personnel.

These techniques are essential for maintaining the integrity of guide wires in overhead power systems.

4.2 Repair and Replacement Procedures

When guide wires are damaged‚ repairs must be conducted promptly to avoid system failures. Technicians first assess the extent of damage‚ ensuring the power line is de-energized for safety. Minor issues‚ such as fraying or corrosion‚ may be addressed with specialized repair kits or sleeves. In severe cases‚ partial or full replacement of the guide wire is necessary. Replacement involves disconnecting the wire‚ removing the damaged section‚ and installing a new one‚ ensuring proper tension and alignment. Post-repair testing‚ including tension checks and visual inspections‚ is essential to restore reliability and safety. Documentation of all procedures is maintained for future reference.

Safety Considerations

Safety considerations for guide wires include de-energizing lines before maintenance‚ wearing personal protective equipment‚ and following established protocols to minimize risks for linemen;

5.1 Hazards Associated with Guide Wires

Hazards associated with guide wires include live wire exposure‚ mechanical failures‚ and environmental risks like extreme weather and wildlife interference. These factors can lead to power outages and safety risks for linemen.

5.2 Safety Protocols for Linemen

Safety protocols for linemen working with guide wires are critical to prevent accidents. Proper training‚ use of personal protective equipment (PPE)‚ and adherence to de-energization procedures are essential. Linemen must ensure lines are grounded before handling and use insulated tools to avoid electric shock. Regular equipment inspections and teamwork coordination further enhance safety. Following industry standards and maintaining clear communication during operations are vital to minimize risks associated with guide wire installations and repairs.

Challenges and Solutions

Guide wires face challenges like harsh weather and aging infrastructure. Solutions include using advanced materials and smart technologies to enhance durability and maintenance efficiency‚ ensuring reliability.

6.1 Environmental Factors Affecting Guide Wires

Environmental factors significantly impact guide wires‚ including extreme weather conditions like heavy rain‚ snow‚ and high winds‚ which can cause mechanical stress and damage. Temperature fluctuations lead to thermal expansion and contraction‚ affecting wire tension. UV exposure accelerates material degradation‚ while humidity and saltwater environments increase corrosion risks. Natural disasters‚ such as earthquakes and floods‚ can displace or damage guide wires. These factors necessitate the use of durable‚ weather-resistant materials and regular maintenance to ensure long-term reliability and safety in power distribution systems.

6.2 Innovative Solutions for Durability

Innovative solutions enhance guide wire durability‚ such as using high-strength‚ weather-resistant materials like galvanized steel and composite fibers. Coatings with corrosion-inhibiting properties extend lifespan. Smart technologies‚ including sensors for real-time monitoring‚ detect issues before failures occur. Additionally‚ ergonomic designs reduce mechanical stress‚ and lightweight materials ease installation. These advancements ensure guide wires withstand harsh conditions and last longer‚ improving grid reliability and reducing maintenance costs.

Future Trends in Guide Wire Technology

Future trends include advancements in material science and integration of smart technologies‚ enhancing durability and real-time monitoring for improved reliability and performance in power distribution systems.

7.1 Advancements in Material Science

Advancements in material science are revolutionizing guide wires‚ with high-strength‚ lightweight alloys and composite materials offering enhanced durability and resistance to environmental factors. Researchers are exploring eco-friendly materials that reduce corrosion and improve conductivity‚ ensuring longer lifespans and reduced maintenance needs. These innovations aim to address challenges like sagging and mechanical stress‚ while also integrating smart monitoring capabilities. By leveraging cutting-edge technologies‚ the development of next-generation guide wires promises to significantly improve the reliability and efficiency of power distribution systems worldwide‚ ensuring safer and more sustainable energy transmission.

7.2 Integration of Smart Technologies

The integration of smart technologies into guide wires is transforming power distribution systems by enabling real-time monitoring and predictive maintenance. Sensors embedded in guide wires can detect temperature fluctuations‚ tension levels‚ and potential faults‚ transmitting data to control centers. This allows utility companies to address issues before they escalate‚ reducing power outages and enhancing grid reliability. Smart technologies also facilitate the integration of renewable energy sources and energy storage systems‚ ensuring a more resilient and adaptive power network. These advancements are paving the way for smarter‚ more efficient‚ and sustainable energy distribution infrastructure.

Related posts:

Archives

Calendar

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| 25 | 26 | 27 | 28 | 29 | 30 | 31 |

Leave a Reply

You must be logged in to post a comment.